Why i-spring

i-spring equips mechanical components with smart sensors and real-time analytics to make hidden performance data visible. Our techn ology integrates seamlessly into existing systems, enabling conditional monitoring, predictive maintenance, lifecycle optimization, and data-driven process control.

Unlock operational efficiency, reduce downtime, and build the foundation for intelligent industrial systems.

Book a demoSmart Sensors.

Smarter Decisions.

Our intelligent sensor system wirelessly delivers real-time condition data from mechanical components. Our analytics platform transforms this data into predictive and understandable insights, enabling early detection of critical eventswear, reducing downtime and optimizing maintenance.

The result: lower costs, longer asset life and scalable impact across industries.

Long-lasting energy with flexible options

Intelligence in every movement

Precision at the interface between sensor and component

Our main features

Predictive Maintenance

- Providing the remaining lifetime

- Analyze the dynamic behavior online to detect anomalies and changes

- Used algorithms

- Damage accumulation

- FFT-Analysis

Condition monitoring

- Generate load collectives

- Visualize critical events

- On-board sensors

- 3 grid strain gauge

- 3 axis accelerometer

- Temperature

Measurement and sensing system

- Measuring parameters

- Weight

- Deflection

- Pressure

- Liquid flow

Control system

- Fast sampling rate to enable a control loop

- Measurement directly at heart of operation

Visualisation

- Presentation of results easy understandable

- Data can be viewed after platform log-in on every browser

- Additional export function of data for further assessment

Connectivity to existing systems

- via OPC-UA

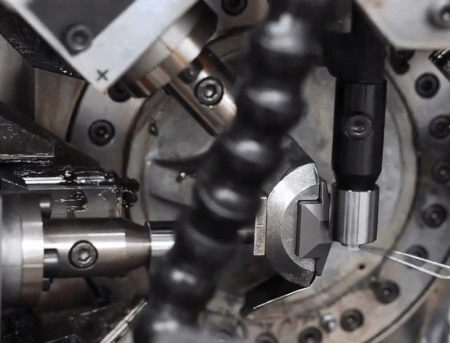

Precision in miniature

The i-spring sensor combines strain, temperature, and acceleration measurement in one compact, wireless system. With cutting-edge multisensor technology and efficient data transmission, it sets new standards for intelligent applications.

Sampling rate

0G-force range

0Battery life

0About us

Integrated and Essential - We believe in innovation as a driver of progress. By making components and their environments intelligent, we unlock access to previously unavailable data and lay the foundation for a smarter, more sustainable, and higher performing industrial future.

We transform mechanical components into intelligent sensor solutions that reliably detect and analyze deformations and environmental influences in real time - user - optimized and precisely targeted.

Our technology empowers developers, manufacturers, and end users of systems and equipment to enable predictive maintenance, enhance operational safety, optimize processes, and use resources more sustainably across industry, infrastructure, and mobility.

We are curious, bold, and always think one step ahead. We challenge the status quo, seek out innovative paths, and act with a solution-oriented mindset. For us, progress stems from deep understanding and continuous improvement. We think analytically, recognize patterns, and translate complex data into clear insights. Our strength lies in delivering relevant knowledge that supports robust, realtime decision-making.

We are committed collaborators who tackle challenges hand in hand with our clients.

To us, collaboration means mutual commitment, transparency, and shared high standards.

Albert Enste

CEO and Founder

Dr. Boris Ouriev

Head of Innovation, Research & Development

Dr. Cord Teller

Head of Sales and Spring Technology Expert

Robert Ingegnoli

Chief Financial Officer